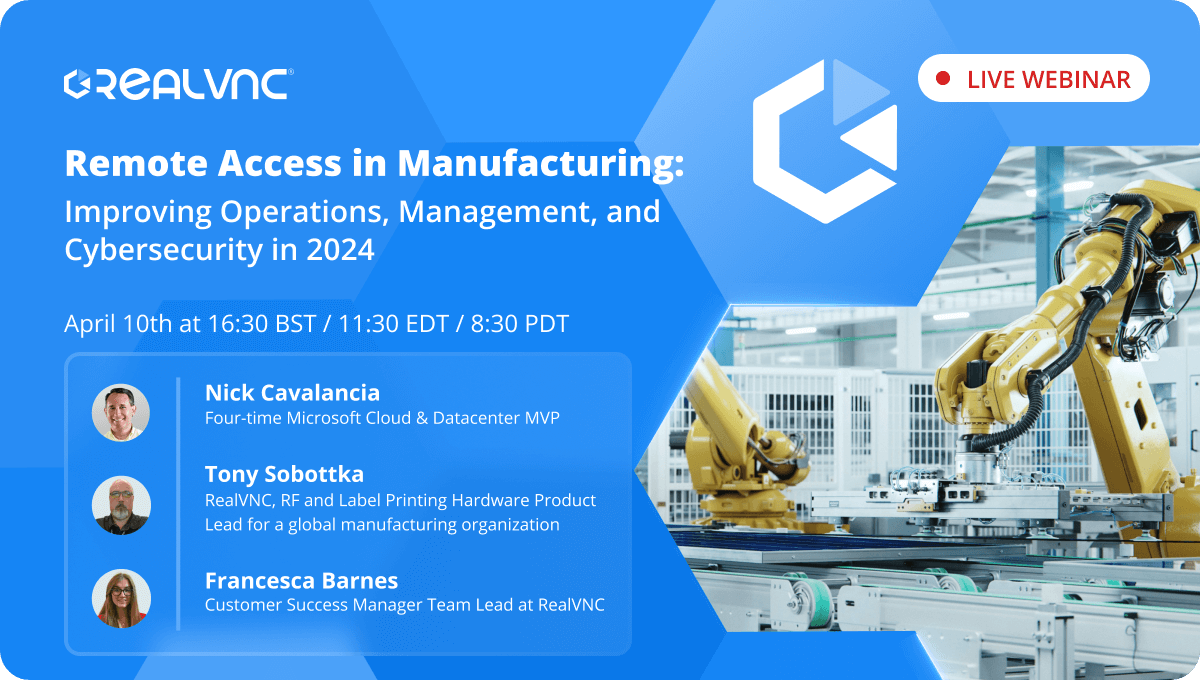

The Industrial Evolution: Remote Access Software Makes Its Presence Felt

Picture your production floor for a moment. All the machinery normally works precisely as it should. But what happens when a critical component suddenly fails?

Typically, this would mean costly downtime and calls to engineers. But with remote access software, the solution is literally at your fingertips; experts can troubleshoot and resolve issues from anywhere in the world. Is it time to reimagine your plant’s response to machinery issues? Absolutely.

Remote access solutions for Manufacturing, like RealVNC Connect – move from reactive to proactive maintenance. It’s not just about firefighting; it’s about gearing your operations toward efficiency.

Unleashing Potential: How Remote Access Improves Operations

- Efficient Problem-Solving – Why wait hours for a specialist when remote access software lets you have an immediate on-screen presence? When machines halt, every second lost also means money lost. Remote access reduces response times from hours to minutes.

- Reducing Downtime: Downtime is the biggest enemy of productivity. Manufacturing remote software solutions is like having a technician hidden in each system, ready to act when needed.

- Streamlining Maintenance Processes: How can engineers manage and maintain machines without setting foot on the factory floor sound? With centralized remote access management, they can provide support as if they were right beside that machine.

Security and Compliance: Non-Negotiable in the Industrial Field

Let’s talk about the elephant in the room: security. The mere thought of remote access sends shivers down the spine of stakeholders. Yet, there are remote access solutions built with security at their heart, ensuring your data is guarded like a military fort.

Cutting-Edge Integration: Harmonizing Factory Systems

The beauty of industrial remote access tools lies in their ability to integrate seamlessly. Whether your setup is full of legacy systems or the latest technology, cross-platform remote access manufacturing software bridges the gap, making sure that you can access them all.

A good remote access solution’s manufacturing integration doesn’t just play well with your devices; it amplifies their capabilities. Unlocking the full potential of your existing systems isn’t a fantasy — it’s a strategic move.

The Real-World Applications

Beyond theory, real-world applications of remote access in manufacturing are telling. From remote machine monitoring manufacturing practices allowing for real-time data analysis to factory systems remote support slashing IT costs, the possibilities are almost endless.

This isn’t about keeping up; it’s about bringing your manufacturing process into the present. As we navigate a competitive industry, those using tools like remote desktop for factories will find themselves ahead of the curve. Will you be at the forefront?

Remote access software for manufacturing isn’t a luxury—it’s a fundamental pillar in the next industrial revolution.

Engage with the future of manufacturing. Explore the potential of remote access software now!